Soil Testing

Soil testing is performed in accordance with ASTM standards to evaluate the physical and mechanical properties of soil, such as classification, compaction, strength, and permeability. These tests provide reliable data for safe land development, foundation design, and construction quality control.

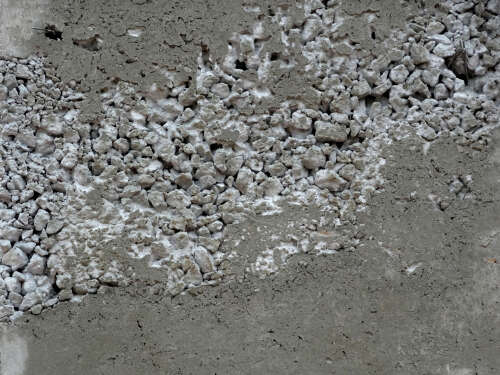

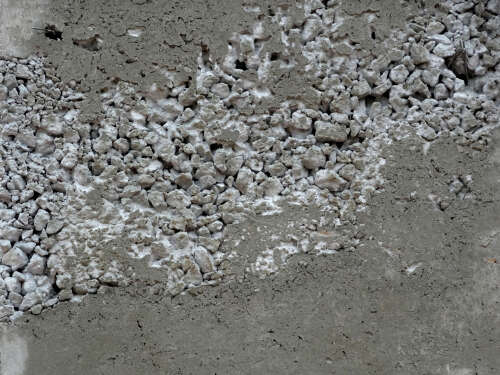

Aggregate Testing

Our aggregate testing services evaluate the quality and suitability of aggregates for construction projects in compliance with ASTM standards. The tests cover particle size distribution, shape and texture analysis, specific gravity, absorption, moisture content, Los Angeles abrasion, impact and crushing resistance, and soundness tests. These assessments ensure that aggregates meet the required specifications for strength, durability, and long-term performance in concrete, asphalt, and other construction applications.

Asphalt and Binder Testing

Our asphalt and binder testing services, performed according to ASTM standards, ensure the quality, performance, and durability of paving materials. We test properties such as penetration, softening point, viscosity, ductility, flash and fire points, binder grading, and Marshall stability of asphalt mixes. These tests help guarantee reliable pavement performance, optimized mix design, and long-lasting road and infrastructure construction.

Cement Testing

Our cement testing services follow ASTM standards to ensure the quality, consistency, and performance of cement for construction applications. Tests include fineness, setting time (initial and final), soundness, compressive strength, consistency, and chemical composition analysis. These evaluations help guarantee that cement meets project specifications, contributes to durable structures, and performs reliably in concrete and masonry works.

Concrete Structure Inspection and failure assessment

We provide comprehensive inspection and assessment services for concrete structures to ensure safety, durability, and compliance with engineering standards. Our services include visual inspections, non-destructive testing (NDT), strength and load capacity evaluation, crack and defect analysis, and failure investigation. By identifying structural weaknesses and root causes of failure, we help clients implement effective repair, rehabilitation, and maintenance strategies to extend the lifespan of concrete assets.

Structural Integrity , defect and voids in concrete & rock

We specialize in evaluating the structural integrity of concrete and rock formations, detecting defects, voids, and other anomalies that could compromise safety and performance. Using advanced non-destructive testing (NDT) techniques, ultrasonic testing, ground-penetrating radar, and core sampling, we identify hidden weaknesses and provide detailed assessments. Our services support effective repair, reinforcement, and maintenance strategies, ensuring long-term reliability of structures and geotechnical assets.

Durability Assessment of Reinforced concrete Structure

We provide comprehensive durability assessments of reinforced concrete structures to evaluate their long-term performance and resistance to environmental and operational stresses. Our services include chloride penetration testing, carbonation depth measurement, corrosion evaluation of reinforcement, and exposure condition analysis. These assessments help identify potential deterioration, guide maintenance strategies, and ensure the structural longevity and safety of concrete assets.

Chemical & Water Testing

Our tests include pH, hardness, total dissolved solids, chloride content, sulfates, heavy metals, and other chemical parameters, following ASTM and relevant standards. These analyses help monitor water quality, detect contaminants, and provide reliable data for process optimization, environmental protection, and regulatory compliance.

NDT Compression test by Schmidt Hammer

We perform non-destructive compression testing using the Schmidt Hammer to quickly assess the surface hardness and estimated compressive strength of concrete structures. This method provides reliable, on-site evaluation without damaging the structure, making it ideal for quality control, structural assessment, and maintenance planning.

NDT by Pulse Velocity for concrete

We use the Pulse Velocity method for non-destructive testing to evaluate the quality, uniformity, and integrity of concrete structures. By measuring the travel time of ultrasonic pulses through concrete, this technique detects cracks, voids, honeycombing, and other internal defects, providing valuable information for structural assessment and maintenance planning without damaging the structure.

Core Drilling

Core drilling is a precise method for extracting cylindrical samples from concrete, asphalt, or rock for detailed laboratory testing. It allows assessment of compressive strength, density, moisture content, and internal defects while minimizing structural damage. Core samples provide critical data for quality control, failure analysis, and engineering evaluations of existing structures.

Mortar Testing

Our mortar testing services evaluate the quality, strength, and durability of mortar used in masonry and construction applications. Tests include compressive strength, consistency, workability, setting time, and adhesion, in accordance with ASTM standards. These assessments ensure that mortar meets project specifications, contributes to structural stability, and performs reliably over time.

Steel Rebar Testing

We provide comprehensive testing of steel reinforcement bars (rebar) to ensure strength, durability, and compliance with ASTM and relevant standards. Our services include tensile testing, bend and rebend tests, chemical composition analysis, and elongation measurements. These tests guarantee that rebar meets project specifications and contributes to the safety and structural integrity of concrete constructions.

Rebar Locator & cover distance measurement

We use advanced rebar locators to detect the position, size, and layout of steel reinforcement within concrete structures. Additionally, cover distance measurement ensures that the concrete cover over the reinforcement meets design specifications, providing protection against corrosion and contributing to the overall structural durability and safety.

Bitumen Testing

Our Superpave testing services evaluate asphalt mixtures to ensure optimal performance, durability, and resistance to rutting and cracking under traffic and environmental conditions. Tests include aggregate characterization, binder performance grading, volumetric mix design, and rutting and fatigue analysis. These assessments help design high-quality pavements that meet project specifications and long-term performance requirements.

Superpave testing

We use the Pulse Velocity method for non-destructive testing to evaluate the quality, uniformity, and integrity of concrete structures. By measuring the travel time of ultrasonic pulses through concrete, this technique detects cracks, voids, honeycombing, and other internal defects, providing valuable information for structural assessment and maintenance planning without damaging the structure.

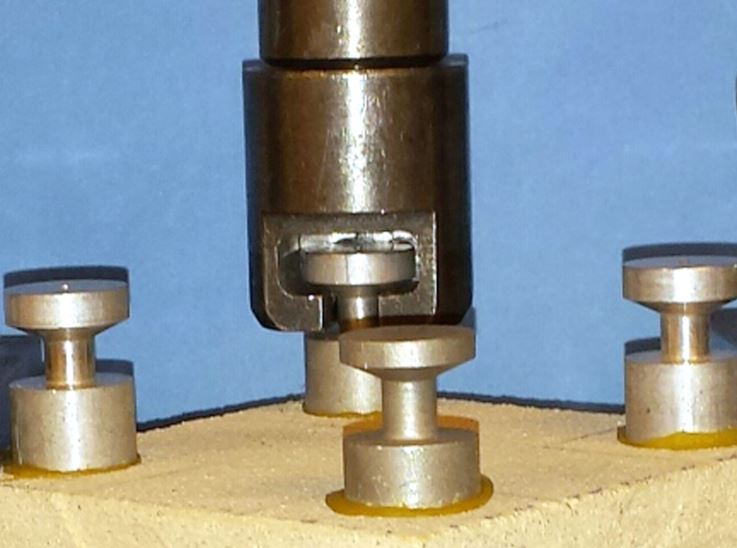

Pull Off Test

The Pull-Off Test measures the adhesion strength of coatings, concrete overlays, or bonded materials to assess their bond quality and durability. By applying controlled tensile stress until failure occurs, this non-destructive test helps identify weak spots, ensure proper surface preparation, and guide maintenance or repair strategies for long-lasting structural performance.

Field Testing by NDG

We perform on-site non-destructive testing (NDT) to evaluate the integrity, quality, and safety of structures without causing damage. Techniques include ultrasonic testing, radiography, magnetic particle testing, and visual inspections, allowing immediate assessment of welds, concrete, metals, and other materials. Field NDT ensures reliable performance, early defect detection, and supports maintenance and quality assurance programs.

Concrete coating Thickness measurement

We provide precise measurement of concrete coating and overlay thickness to ensure uniform application and compliance with design specifications. Using non-destructive techniques, our services help verify protective coatings, detect inconsistencies, and support quality control, maintenance planning, and long-term durability of concrete structures.

Field Testing by Electrical Density Gauge

We perform on-site soil and asphalt density testing using electrical density gauges to quickly and accurately determine compaction levels. This non-destructive method ensures that materials meet project specifications, supports quality control, and helps optimize construction processes for safe and durable infrastructure.

Pavement Investigation

Our pavement investigation services assess the condition, performance, and structural integrity of roads, highways, and airport pavements. Using techniques such as visual inspection, non-destructive testing, core sampling, deflection measurement, and material analysis, we identify distresses, evaluate load-bearing capacity, and provide recommendations for maintenance, rehabilitation, or reconstruction to ensure safe and long-lasting pavement performance.

Structure and Foundation Testing

We provide comprehensive testing and evaluation of structures and foundations to ensure safety, stability, and compliance with engineering standards. Our services include load testing, settlement monitoring, strength assessment, non-destructive testing (NDT), and soil-structure interaction analysis. These assessments help identify potential weaknesses, guide maintenance and repair strategies, and ensure long-term reliability of buildings, bridges, and other infrastructure.

Asphalt Mix Design

Our asphalt mix design services develop optimized mixtures of aggregates and binders to achieve maximum performance, durability, and resistance to traffic and environmental stresses. Using methods such as Marshall and Superpave designs, we evaluate volumetric properties, stability, flow, and compaction to ensure compliance with project specifications. Proper mix design enhances pavement life, reduces maintenance costs, and ensures safe, reliable road surfaces.

Brick & Block Testing

We provide comprehensive testing of bricks and blocks to ensure their quality, strength, and durability for construction applications. Tests include compressive strength, water absorption, density, dimensional accuracy, and efflorescence, following ASTM and relevant standards. These evaluations help guarantee that masonry units meet project specifications and contribute to the safety, stability, and longevity of structures.

Technical Consultancy

We provide expert technical consultancy services across construction, material testing, and industrial projects. Our team offers guidance on project planning, design evaluation, quality assurance, compliance with standards, and problem-solving for complex engineering challenges. By combining technical expertise with practical experience, we help clients optimize processes, ensure safety, and achieve efficient and reliable project outcomes.

Ability to establish Site/ Mobile Laboratory

We have the capability to establish fully equipped site and mobile laboratories for on-site testing and quality control. These laboratories enable real-time analysis of soil, concrete, asphalt, aggregates, and other construction materials, ensuring immediate results, compliance with standards, and efficient project management. Our mobile labs support rapid decision-making, reduce downtime, and maintain high-quality construction practices directly at the project site.